Vertiv™ Liebert® EFC allows hyperscale and colocation clients to easily flex between operating modes for zero water waste and utmost efficiency

Vertiv (NYSE: VRT), a global provider of critical digital infrastructure and continuity solutions, today announced a significant upgrade of its thermal management product portfolio with the introduction of the next-gen Vertiv™ Liebert® EFC free cooling unit with low-GWP (Global Warming Potential) refrigerant. The solution is designed to meet stringent environmental standards for data center applications, including colocation and cloud services, and is now available across Europe, Middle East and Africa (EMEA) with capacities ranging from 150 to 450 kW.

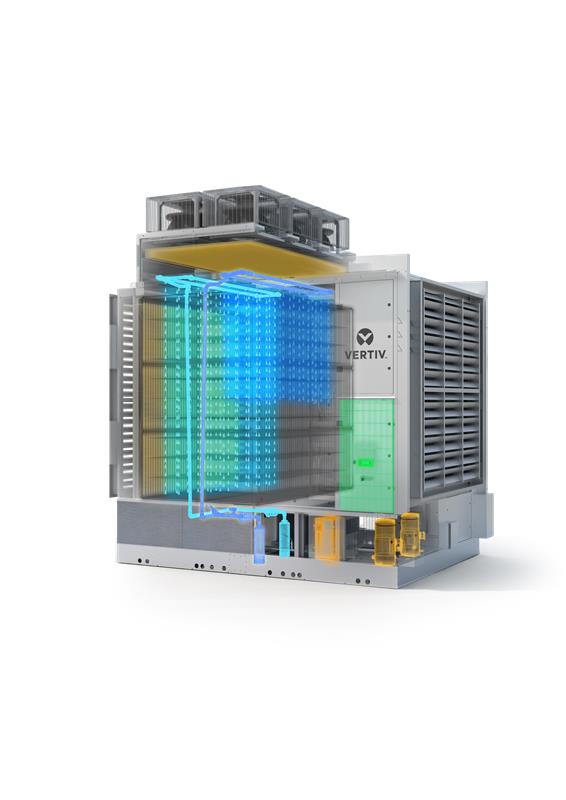

Vertiv Liebert EFC combines the capabilities of indirect air-to-air heat exchange and evaporative cooling principles in a single unit. The innovative patented polymer heat exchanger and the new low-GWP inverter driven compressor technology significantly enhance annual efficiency by up to 19% compared to previous technologies, allowing a pPUE (partial Power Usage Effectiveness) as low as 1.05.

One of the standout benefits of the Liebert® EFC is its extreme flexibility. Based on onsite-specific conditions, a live toggling control feature allows users to seamlessly and securely reduce the use of critical resources like power or water via software controls, to leverage the free cooling mode. This flexibility empowers data centre owners to reduce their climate impact while enabling continuous cooling, regardless of site-specific resources. Models are available with full direct expansion (DX) back-up with a remote condenser, to supply the entire cooling capacity without any water requirements – offering full water independence, without impacting reliability.

“As businesses prioritize sustainability strategies, customers are increasingly seeking innovative cooling solutions that reduce resource consumption while offering operational flexibility and resilience,” stated Sam Bainborough, vice president, thermal business EMEA at Vertiv. “The Liebert EFC, with its game-changing and patented technology, addresses these needs with a flexible system that delivers an entirely new experience for the customer, maximising time using free cooling and leveraging the natural power of evaporation.”

The new Liebert EFC complies with current global regulations and bans (EU F-Gas regulation 2024/573, and IPCC AR4), offering a turnkey solution engineered for future scalability, easy maintenance, and durability. The polymer design offers improved corrosion resistance and also allows a wider range of water qualities during operation when compared to an aluminum heat exchanger. At the core of this cutting-edge solution is Vertiv™ Liebert® iCOM™ and its control algorithms, which manage automatic transitions between the most suitable working modes, enabling use of the preferred cooling source. The controls also enable seamless coordination of units, allowing them to function as a unified system, enhancing cooling continuity and reliability without the need for an additional plant management system.

For more information on the Vertiv™ Liebert® EFC or other Vertiv power and thermal management solutions, including direct-to-chip, immersion (coming soon in EMEA), chilled water, direct expansion, edge and system control technologies, visit Vertiv.com.