BASF and MAN Energy Solutions have entered into a strategic partnership to pursue the construction of an industrial-scale heat pump at the BASF site in Ludwigshafen. This project is intended to make an important contribution to reducing greenhouse gas emissions, establishing the use of low-CO2 technologies in chemical production and reducing the site’s natural gas consumption. As a first step, the project partners are conducting a feasibility study that is expected to be completed by the end of 2022.

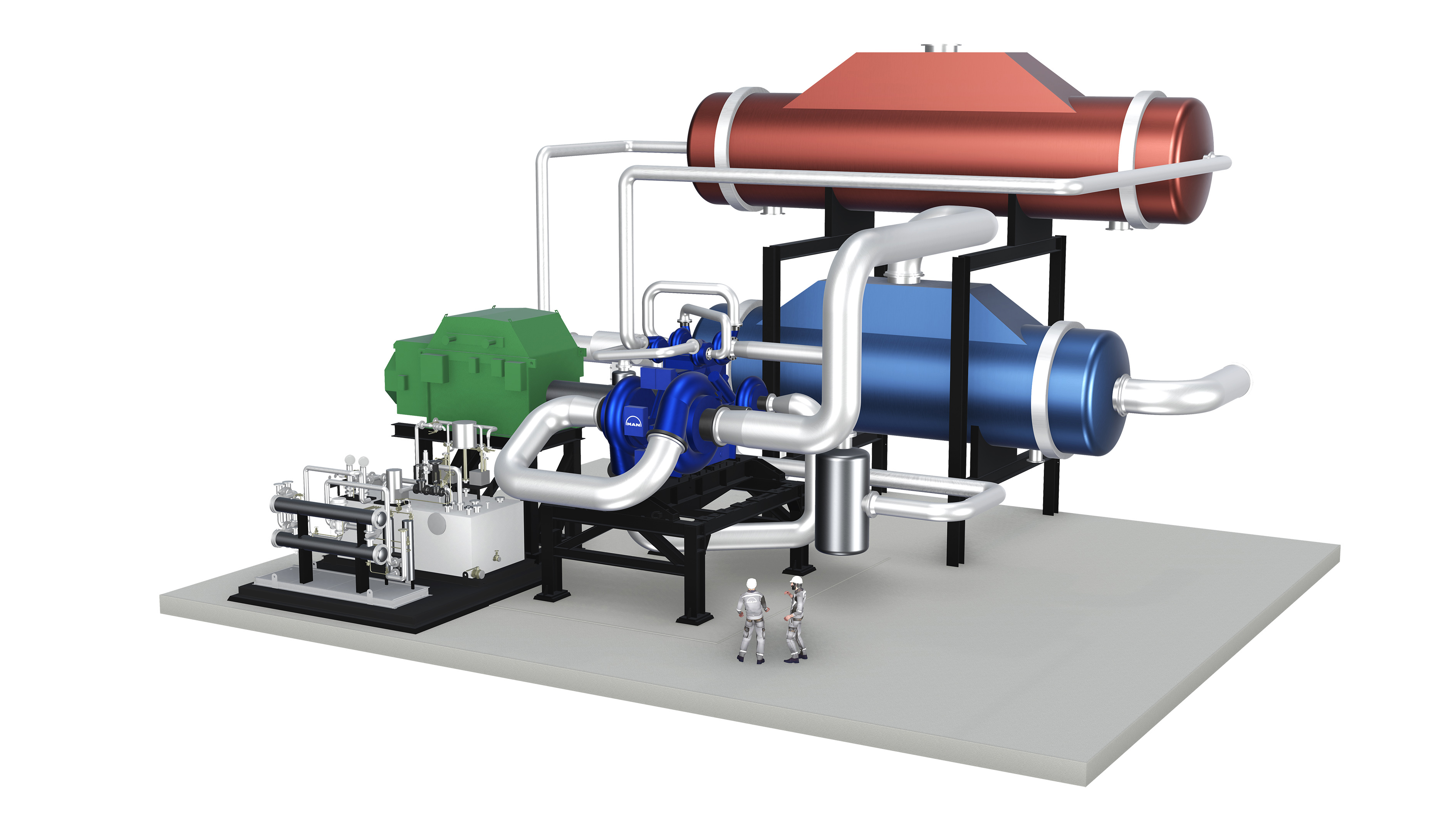

The planned large-scale heat pump will enable production of steam using electricity from renewable energy, tapping waste heat from the cooling water system at BASF as a source of thermal energy. The residual heat in the water will be processed using compression to produce steam that will be fed into the site’s steam network. By integrating the planned heat pump into the site’s production infrastructure, up to 150 metric tons of steam can be produced per hour, equivalent to a thermal output of 120 megawatts. The project could reduce CO2 emissions at the site by up to 390,000 metric tons per year. At the same time, it would make the cooling water system more efficient and less dependent on climate and weather conditions.

The planned large-scale heat pump will enable production of steam using electricity from renewable energy, tapping waste heat from the cooling water system at BASF as a source of thermal energy. The residual heat in the water will be processed using compression to produce steam that will be fed into the site’s steam network. By integrating the planned heat pump into the site’s production infrastructure, up to 150 metric tons of steam can be produced per hour, equivalent to a thermal output of 120 megawatts. The project could reduce CO2 emissions at the site by up to 390,000 metric tons per year. At the same time, it would make the cooling water system more efficient and less dependent on climate and weather conditions.

Steam is the most important source of energy in the chemical industry. In Ludwigshafen, BASF requires around 20 million metric tons of steam per year. The plants at the site use much of this as process steam in production, for example, to dry products, heat up reactors or for distilling. Around half of the steam required at the Ludwigshafen site is already produced by recovering heat from production facilities using a low-CO2 process. The remaining steam demand, approximately 50 percent, is met by gas and steam power plants, which emit CO2 during generation.

Dr. Martin Brudermüller, Chairman of the Board of Executive Directors of BASF SE: “In the medium term, we want to reduce our CO2 emissions by 25 percent by 2030. The use of technologies such as large heat pumps, which already exist and can be scaled up to industrial size, brings us a lot closer to this goal. In our cooperation with MAN Energy Solutions, we combine the expertise of a chemical Verbund site with the know-how required for the technological implementation of a project like this. This technology also has the potential to pave the way for projects at other BASF sites.”

Dr. Uwe Lauber, CEO of MAN Energy Solutions SE, commented: “We are really looking forward to the close collaboration with BASF. Space heating and process heat account for around one-third of German greenhouse gas emissions. Together with BASF, we want to address this significant lever with an innovative solution. We are convinced that our heat pump solution can make a decisive contribution to a climate- friendly supply of steam at the Ludwigshafen site. BASF is a global pioneer in the energy transformation in the chemical industry, a role model for the deployment of innovative technologies to protect the planet, and a great project partner. Industry and climate protection both rely on the innovations that arise from such strong partnerships.”

Dr. Uwe Liebelt, President European Verbund Sites, BASF SE: “The transformation that lies ahead of us requires, above all, openness to new technologies. In Ludwigshafen, we are testing and developing several technologies and alternative processes to replace fossil fuels – this includes the electrical production of steam. Protecting the climate means not only avoiding greenhouse gas emissions but also using energy sustainably – industrial heat pumps enable both. In the future, they will be an essential part of the sustainable energy infrastructure at the Ludwigshafen site.”

With this project, the two partners want to gain experience in the integration and operation of industrial-scale heat pumps and pave the way for the standardization and deployment of the technology at other sites. The feasibility study’s findings with regard to the economic viability, efficiency and competitiveness of the technology will form the basis for the subsequent decision-making process for the construction of the heat pump.

BASF has set itself the goal of achieving net zero CO2 emissions by 2050. In addition to the use of renewable energies and increasing energy efficiency in production, new technologies such as the electrification of steam production will contribute to meeting this target. Scaling up such climate-friendly processes to an industrial level will decisively influence the transformation to low-CO2 chemical production.

MAN Energy Solutions has put technical solutions to lower greenhouse gas emissions from industry, energy production and shipping at the heart of its future strategy. In addition to technologies to avoid harmful emissions, the company focuses in particular on the reduction or compensation of unavoidable residual emissions from industry.